Welcome to the official website of Changsha Xiangneng Oil Filter Machine Manufacturing Co., Ltd.!

Cleanliness NAS6 grade oil filter, package inspection!

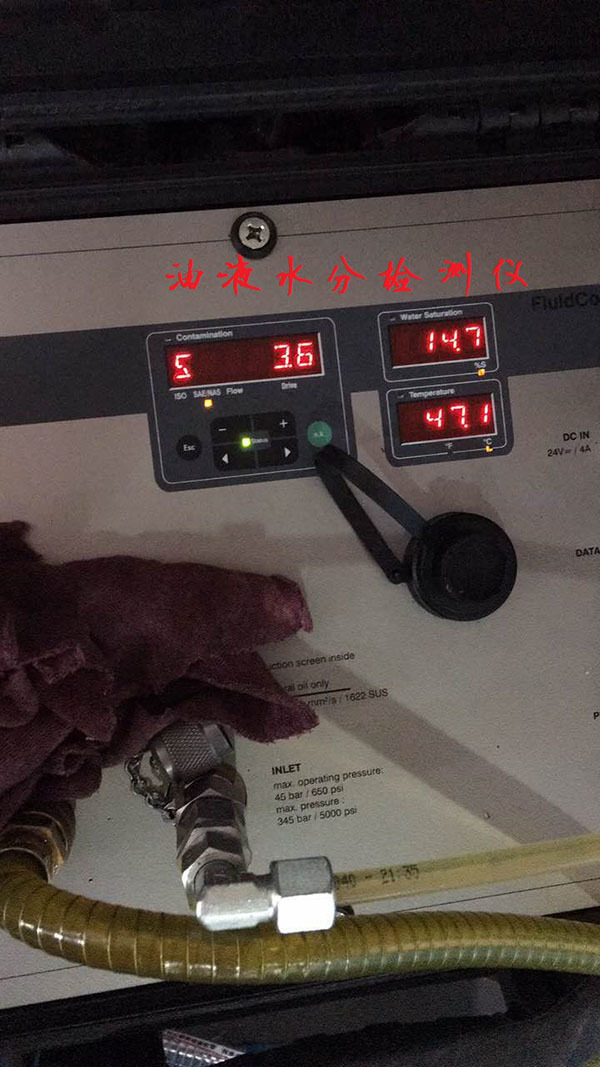

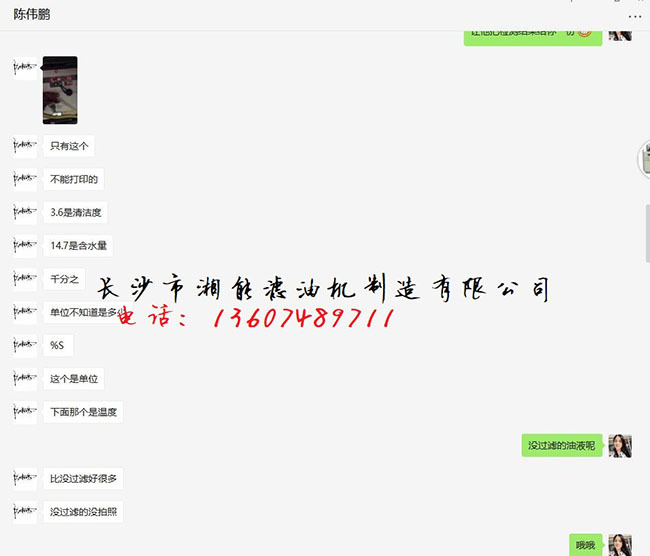

Nanjing Eston Automation Co., Ltd. covers a wide range of production, development, and service of various types of mechatronic products, automation and control. The hydraulic oil cleanliness rating requirements for the lubrication system meet NAS1638 Level 6. The above picture shows the results of the high-efficiency hydraulic oil vacuum filter oil filter, after the test of the Hedeke brand particle moisture detector: the water content of the oil contains all the particle impurities.

use

1. Recycling of high-precision lubricating oils such as unqualified hydraulic oil, refrigeration oil, gear oil, and anti-wear hydraulic oil.

2. It is used for the purification of lubricating oils such as mechanical oil, cooling oil, gasoline engine oil, diesel engine oil and heat treatment oil in the fields of machinery, metallurgy, mining, petroleum, chemical, electric power, transportation and railway.

3. It is used to filter the harmful components such as moisture, impurities and volatiles (such as ammonia) in the oil to ensure the normal operation of the hydraulic system, power system and lubrication system.

Technical characteristics

1. Strong ability to filter out impurities. Large-area, deep-level precision filter material can remove fine particles in oil, and equipped with permanent magnet filter to filter out fine impurities containing iron.

2, unique degassing, dehydration system, using three-dimensional evaporation technology, multi-layer oil-water separation technology, rapid separation of water and gas in the oil.

3. The heating system adopts the optimized pipeline design to ensure uniform heating and stable oil temperature.

4, advanced automatic constant temperature control, automatic liquid level control, automatic defoaming control, automatic pressure protection and sophisticated configuration to ensure high-performance operation of equipment.

5, online filter oil, can be run unattended, the operating status is indicated by the indicator light.

6, the use of differential pressure automatic backwash system to eliminate the complicated manual washing and washing.

User selectable configuration

1. According to the user's needs, optional PLC intelligent control, touch screen operation, and dynamic display.

2. The main power components, filter equipment and electrical components can be selected with high quality imported products to improve the performance of the equipment.

3. Optional flow meter with accumulative function.

4, according to the use of the site safety environment, optional BT or CT grade explosion-proof.

User selectable machine structure

1. The structure of the whole machine can be made into mobile and fixed.

2, can be made into a fully enclosed, concealed, canvas, open type.

3. The color of the device can be arbitrarily selected as needed.

technical parameter

| Indicator name | unit | TYA-10 | TYA-20 | TYA-30 | TYA-50 | TYA-100 | TYA-150 | TYA-200 |

| flow | L/min | 10 | 20 | 30 | 50 | 100 | 150 | 200 |

| Working vacuum | Mpa | 0.035 | ||||||

| Work pressure | Mpa | ≤0.4 | ||||||

| Constant temperature control range | ℃ | 0-100 | ||||||

| Moisture | PPM | ≤50 | ||||||

| Cleanliness | NAS | ≤6 | ||||||

| power supply | ~50Hz380V (according to user requirements) | |||||||

| Working noise | dB(A) | ≤75 | ≤75 | ≤75 | ≤78 | ≤78 | ≤78 | ≤80 |

| Emulsification value | min | New oil ≤ 15min, running oil ≤ 30min | ||||||

| Electric heating power | KW | 30 | 30 | 30 | 30 | 45 | 45 | 60 |

| Total electric power | KW | 33 | 33 | 35 | 35 | 48 | 50 | 65.5 |

| Inlet (out) port diameter | mm | 25 | 25 | 25 | 32 | 42 | 50 | 60 |

| equipment weight | kg | 400 | 425 | 450 | 475 | 525 | 580 | 650 |

| Dimensions | mm |

1500*100 *14000 |

1500*1050 *1400 |

1500*1050 *1450 |

1600*1150 *1600 |

1750*1250 *1700 |

1900*1400 *1750 |

2100*1500 *1900 |

※ The device dimensions and equipment weight are for reference only. As the product continues to evolve, the actual product will prevail.

Hotline: 13607478711

Lubricating oil vacuum oil filter working principle

Vacuum oil purifier is designed according to the different boiling point of water and oil. It consists of vacuum heating tank, fine filter, condenser, prefilter, water tank, vacuum pump, oil drain pump and electrical cabinet. The vacuum pump draws out the air in the vacuum tank to form a vacuum. Under the action of atmospheric pressure, the external oil enters the primary filter through the inlet pipe, removes the larger particles, and then enters the heating tank, and the oil is heated to 40~75 °C. Automatic oil bleed valve, which automatically controls the amount of oil entering and leaving the vacuum tank. The heated oil is rapidly swirled by the spray wings to separate the oil into a semi-mist, and the water in the oil is rapidly evaporated into water vapor and continuously sucked into the condenser by the vacuum pump. The water vapor entering the condenser is cooled and then returned to the original water for release. The oil in the vacuum heating tank is discharged into the fine filter by the oil discharge pump, and the particulate impurities are filtered out through the oil filter paper or the filter element, thereby completing the vacuum oil filter quickly. Remove the impurities, water and gas from the oil, so that the clean oil is discharged from the oil outlet.