Welcome to the official website of Changsha Xiangneng Oil Filter Machine Manufacturing Co., Ltd.!

ake off the water vacuum oil filter, Xiang can make!

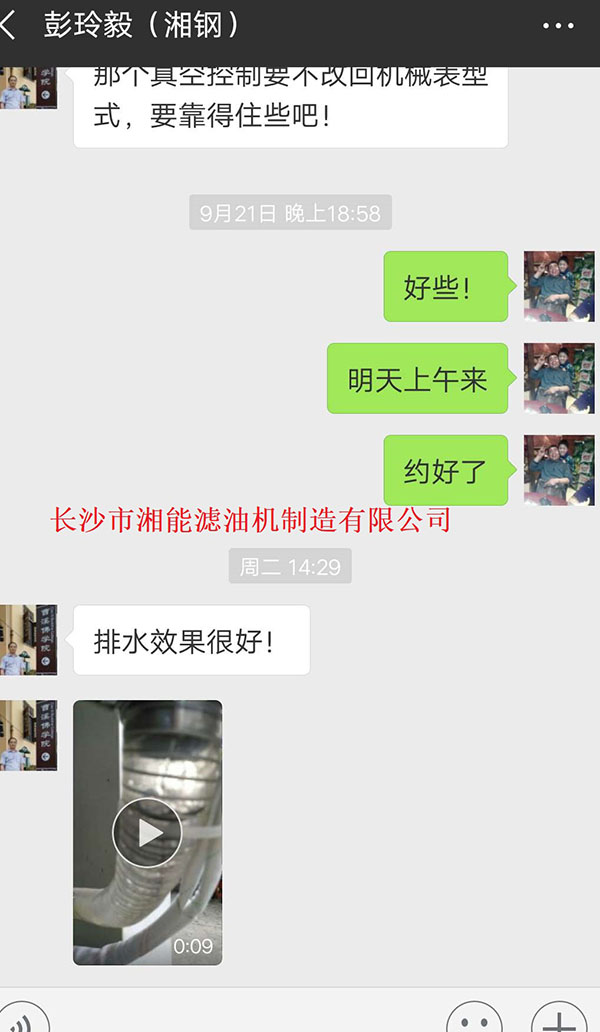

Xianggang has 30 tons of sealed cabinet oil with 20% water content per day. They have used various oil filters from several companies, including centrifugal oil filters, and their work results are not satisfactory. According to the needs of the Xiangtan Iron and Steel Group, our company has built this large-scale vacuum oil filter oil filter, and the drooling of the leeches has brought great convenience to their work!

Product introduction

TYD series vacuum oil filter is especially suitable for turbine oils, hydraulic oils, refrigeration oils and other lubricants that need to remove a large amount of water and achieve precision filtration impurities.

Characteristics

1, remove water, strong demolition ability. It is easy to separate a large amount of water from the oil, and it is also easy to remove trace water in the oil.

2, using special thin film evaporation technology and molecular evaporation technology, can quickly break the emulsification, can make the turbid emulsified oil become clear and transparent.

3, the use of life-long non-change type (more than 20 years) thin film evaporation technology and molecular evaporation technology. It not only relieves the trouble of periodically replacing the emulsified filter element, but also reduces the cost of the oil filter and reduces the labor intensity.

4, strong ability to filter out impurities, automatic backwash filter can remove a large amount of impurities in the oil, large-area deep-level precision filter material can remove fine particles in oil, can be used instead of oil system cleaning device, so that the oil system is seriously polluted It can also be restored to the "Running Turbine Oil Pollution Degree Control Standard".

4. The heating system adopts the optimized piping design to ensure uniform heating and stable oil temperature.

5, advanced automatic constant temperature control, automatic liquid level control, automatic defoaming control, automatic pressure protection and sophisticated configuration to ensure high-performance operation of equipment.

6, online filter oil, can be run unattended, the operating status is indicated by the indicator light.

7, the machine is humanized design, low noise, easy to operate, long service life, energy saving and environmental protection.

8, with filter replacement only, filter saturation device.

9, with leakage, overload load shutdown device to protect the motor.

10, with phase sequence, phase loss protection, accidental shutdown safety control.

Advantage

High degree of automation, compact and lightweight, safe and reliable. This machine adopts the infrared liquid level automatic control device to realize the man-machine separation, simple operation and reliable use.

1. According to the user's needs, optional PLC intelligent control, touch screen operation, and dynamic display.

2. The main power components, filter equipment and electrical components can be selected with high quality imported products to improve the performance of the equipment.

3. Optional flow meter with accumulative function.

4. Optional online moisture detector.

5, according to the use of on-site safety environment, optional BT or CT grade explosion-proof.

User selectable machine structure

1. The structure of the whole machine can be made into mobile and fixed.

2, can be made into a fully enclosed, concealed, canvas, open type.

3. The color of the device can be arbitrarily selected as needed.

Technical data sheet (can be as needed)

| project | parameter name | unit | TYD-50 | TYD-100 | TYD-150 | TYD-200 | TYD-300 | |

| Equipment technical indicators | Traffic | L/H | 3000 | 6000 | 9000 | 12000 | 18000 | |

| Working vacuum | MPa | -0.06~-0.099 | ||||||

| Work pressure | MPa | ≦0.5 | ||||||

| Constant temperature control range | ℃ | 20~80 | ||||||

| power supply | V | 380V/50HZ | ||||||

| Working noise | dB(A) | ≦78 | ||||||

| Trouble free working time | H | ≧4000 | ||||||

| Continuous working time | H | ≧150 | ||||||

| heating power | KW | 30 | 60 | 90 | 120 | 180 | ||

| Total power | KW | 35 | 67 | 98 | 142 | 198 | ||

| Import and export pipe diameter | mm | 32 | 40 | 50 | 60 | 65 | ||

| equipment weight | kg | 530 | 710 | 850 | 950 | 1150 | ||

| Dimensions | long | mm | 1500 | 1600 | 1700 | 1800 | 2000 | |

| width | mm | 950 | 1150 | 1250 | 1300 | 1400 | ||

| High | mm | 1550 | 1650 | 1750 | 1850 | 2000 | ||

| Filtered indicator | Emulsification value | min | ≦15(GB/T7305) | |||||

| Water content | ppm | ≦100 | ||||||

| Gas content | % | ≦0.1 | ||||||

| Cleanliness | NAS | ≦6~9(NAS1638) | ||||||

※ The external dimensions and equipment quality of the equipment are for reference only. As the product continues to develop, the actual product shall prevail.

Contact number: 13607478711